Account of Boeing’s third-party tiers suppliers

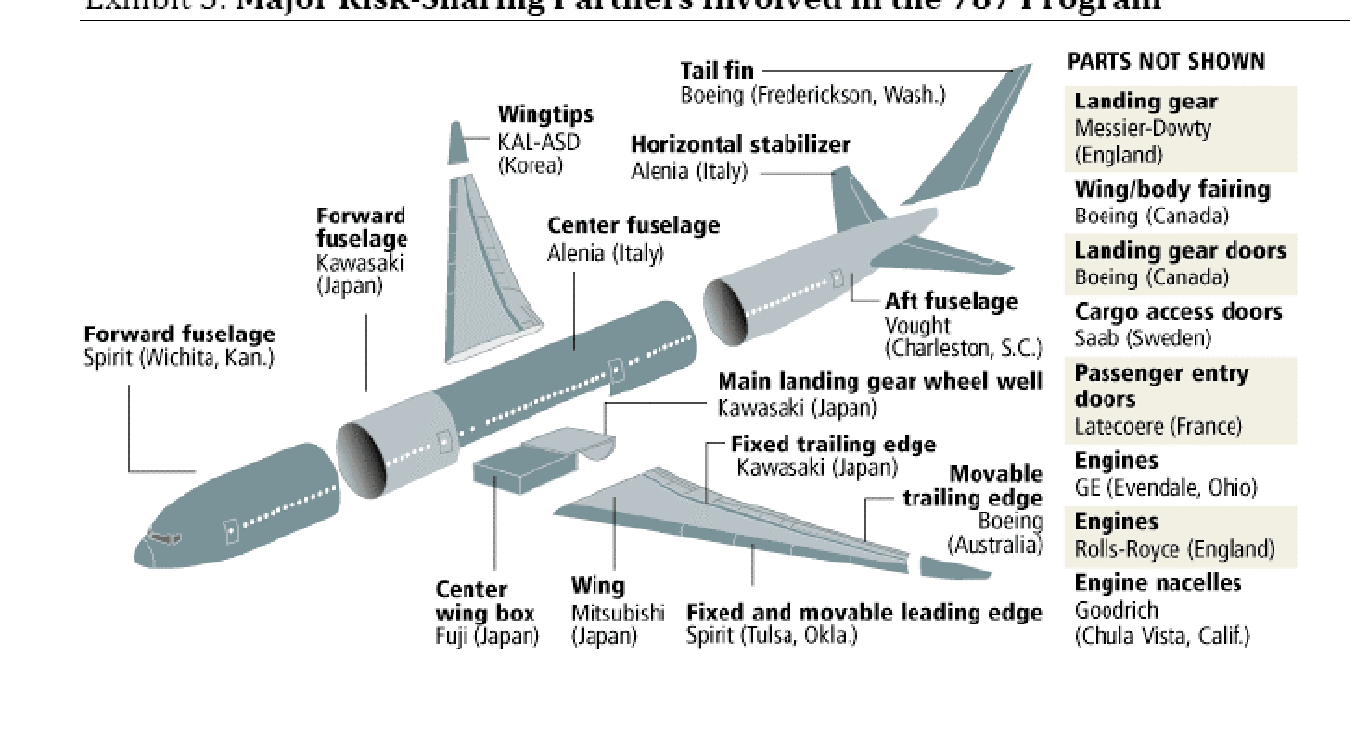

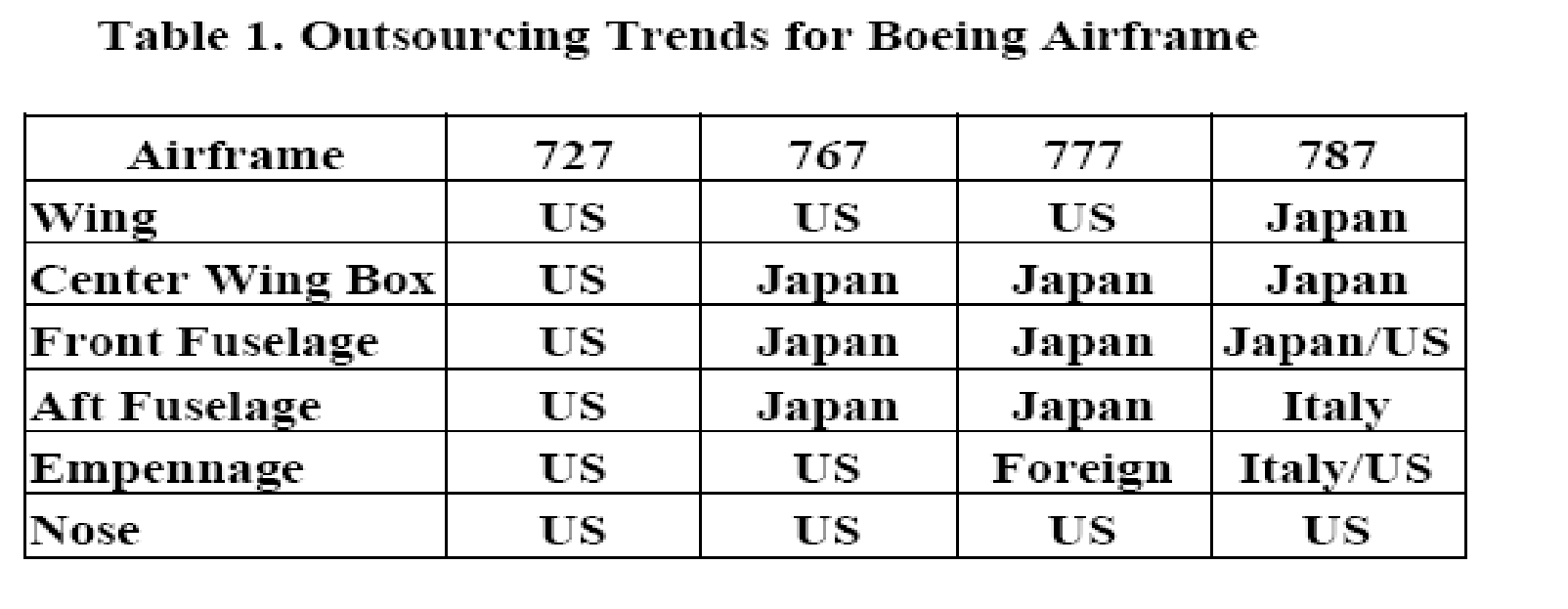

The outsourcing for the manufacturing of aircraft by Boeing has led the way to open the partnering institutes or suppliers to provide their material for the assembly of the world’s largest company’s aircraft. For this direction, the very first step was taken in 1974; when Mitsubishi was given a contract to produce inboard flaps for Boeing 747(Pritchard and Alan, 2005). The imports of parts and aircraft and parts amounted to only 5 percent of aircraft’s value in the 1960s, whereas today is about 45 percent and this content and this content is expected to reach about 70 percent in the context of 787. In comparison to the term of foreign content, it was about 2% for Boeing 727 in the 1960s and for 777 in the 1990’s the foreign content reached up to 30%.

Considering the launch of 787, three Japanese companies are playing their role in the manufacturing process for the final assembly of the wings of 787. No doubt, Japan has competitively acquired the production competence for a wide range of airframe components. The Japanese Aircraft development corporation (JADC) is a combination of Japanese Aerospace companies that are struggling to develop advanced commercial aircraft programs.

The JADC is a neutral aerospace firm found for the improvement of Japan’s Aircraft Industry with the permit of the Japanese government and is organized by the executives of the following aircraft organizations (FAC, 2004).

- Mitshubishi Heavy Industries, Ltd. (MHI)

- Fuji Heavy Industries Ltd.

- ShinMaywa Industries Ltd.

- Japan Aircraft Manufacturing Co., Ltd.

- Ishikawajima-Harima Heavy Industries Co., Ltd.

- Japan airline Co., Ltd

- All Nippon Airways Co., Ltd

- Japan Air System Co., Ltd

Following is the data of outsourcing from just one company i.e. Mitshubishi just to give an idea about the status of the parts from this company (Pritchard and MacPherson, 2005). This data illustrates a sketch of the parts of the respective plane and the respective number that was actually imported by Boeing from Mitshubishi.

- Inboard TE Flaps 747 (400)

- Inboard Flaps 737 (800-900)

- Passengers entry doors 777 (200-300)

- Fuselage section,46,47,48,777(200)

- Bulk cargo door 777(200)

- Entry service doors 767

- Fuselage section, 46, 777

Brief Survey of Company’s Success Strategy

Boeing Company was founded in 1916 in the Puget Sound region of Washington State. Today it is working as the top market leader in the production of military and commercial Aircraft. It is from the renowned US exporter organizations which facilitate airlines and U.S Allied Government users in over 90 different countries across the globe. Boeing company has gained so much popularity in the past few years and nowadays, it’s working with international standards and a number of clients really admire its strategies and policies. It has its outlets in over 90 different countries across the world.

The mission statement of Boeing Establishment

This International Aerospace company was established with an aim of connecting and protecting People Globally with a mission statement of

Strategic Analysis of Boeing

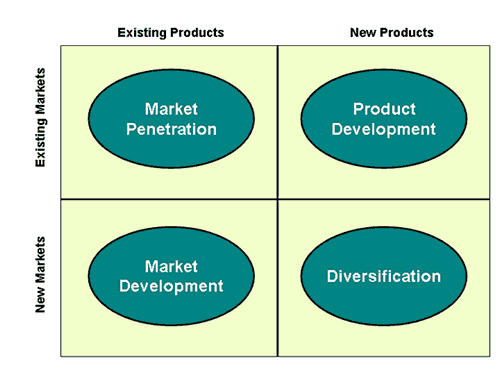

The strategic analysis of Boeing puts for the different strategies that have been playing a role in the success of the Boeing Company;

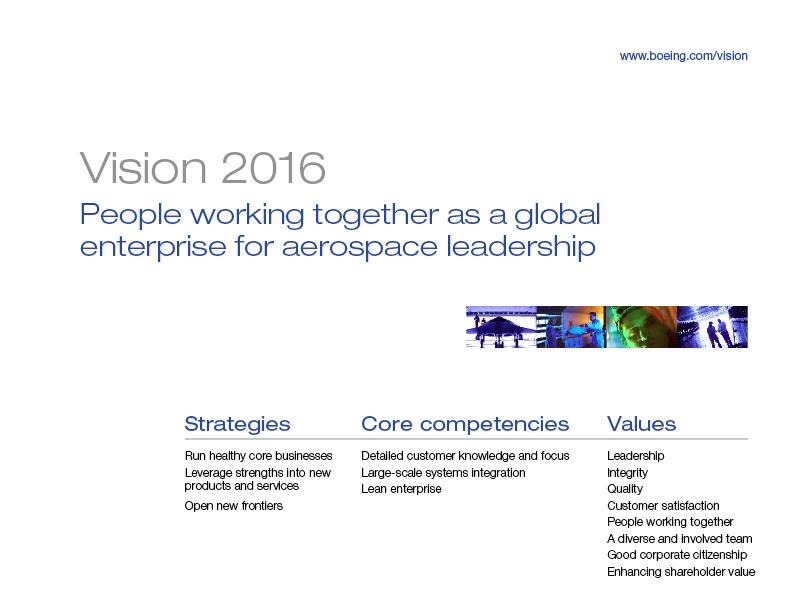

Vision Strategy

The vision of a company dictates where that company wants to be in the future. It ultimately points outs the direction and the limits of the success of the company. The more widened the vision of a company the more is the attainable height of success.

P.E.S.T Strategy

This tool should be efficient enough to present a broad and amalgamated analysis of the following four strategies of the company.

- Political; it involves a deep analysis of the local, national and international political situation and their impact on the growth of the organization.

- Economic; it analyzes the economical variation and its impact on business strategies.

- Social; it focuses on the developing trends of the society and their possible impacts on the organization. This pre-visualizes the importance of industry in the upcoming days.

- Technological; This actually helps to meet the upcoming needs of the technology and to meet and beat the competition.

SWOT Analysis

This analysis consists of:

- Strengths

- Weaknesses

- Opportunities

- Threats

For example for an Aerospace industry following is the conclusion of SWOT analysis;

Successful Corporate Strategy of Boeing

The easiest demonstration of the corporation policy of Boeing divides into three elements: products/services, community engagement and business practices.

The company’s corporate strategy is basically footed on nine different but extremely related tools which are helping in the best organization of the company. The company profile actually covers two basic lines of separate business in one service i.e. Commercial Airplanes and Defense, Space and security.

Main Goals of Corporate:

- Global Growth Strategies

- Quality of the Service

- Providing Best services, Best Products in Best Prices

- Ethics & Compliance

- Leadership Promotion

Improvement Suggestions

Although Boeing is already at the peak of its excellent services the attention towards the core competencies keeping in view the market competition should be reconfigured. Agor, the President of Associated Aircraft Group. Inc (AAG) supported the improvements of AAG, with his safe dedication to quality service, safe operation, and user satisfaction as a quality mark of the company. In this instance following are the key recommendations for Boeing to be focused on.

Detailed customer understanding

There is a requirement to discover more about customers understanding and ability to act and anticipate and be alert to the customer’s needs.

Quality of service needs permanent and extended Focus

A continuous strive for the maintenance of the premier ranked services should be maintained for competing in the World’s Aircraft industry and being the top choice for its clients.

Customer Satisfaction

Satisfaction of Customers is the secret of success behind Boeing Services. It should be enhanced and the delivery of the services should focus on customers’ needs and particularly their satisfaction to keep going this relationship for the long run.

Involvement of a Diverse and fully equipped Team

In the long run the focusing measures for the team selection should need a little improvement and the involved team should be fully valued for the skills, strengths and latest perspectives for the growth and customer satisfaction.

Strategies for Company’s culture and workforce

According to a detailed analysis there are the following strategies that can be adapted for the future perspectives of the Boeing Company.

Organization of Cultural diverse workforce

There is no doubt that cultural diversity is the source of international competitive advantage. As the business of Boeing airplanes is expanding across different countries thus becoming global, thus it means that there is a need of adapting to national and local aspects. Appreciating and understanding the ways to manage the different cultural aspects within the team will help the company to keep nurturing flawlessly.

Enormous Marketing Efforts

Marketing is the most active and important part of the business as it imparts very direct effects on the business growth provided if the marketing is done in an organized and effective way. So considering the competitive situation of the market Boeing should not ignore the need to attract its customers by just making a few promotions and activities. For the correct marketing efforts, there is a need for the understanding of the correct situation of the market and the competition.

So to get through the industrial market following should be the strategy:

- The technical characteristics of the product are important.

- These products directly affect the operations and economic health of the customer.

Strong Business Strategy

Boeing should keep continuing its strong business strategy thus following the 7P formula of business.

Boeing 787 –An Ambitious product Development

The Development of this interesting product Boeing 787 has served as one of the biggest historical and commercial development of Boeing Co., Ltd.

The objective

The objective of this novel task was to create new technology that can reduce weight and fuel usage, reinvent several production procedures, and to give Airline users with a competitive advantage by planning the personal relaxation of the passengers.

Beginning of the Concept

The 787 concept didn’t begin as a super-fuel efficient Dreamliner, but in fact, Bair traces the origins of the 787 in the mid-1990s when there was a need to put together a replacement for the Boeing 767. The 767 was getting beaten in the marketplace by an Airbus A330-220. Thus the market analysis at that time concluded that there is a need of Boeing 787-an airplane with 200-250 seats but with a long-range Potential.

The Timeline for the development of 787

Boeing’s 787 launches were timelined for the last week of 2007, but it lapsed for May 2008, and even this project’s timeline was far too ambitious. The new schedule, therefore, pointed the End of 2008. Discussing the delay Scott Carson, Boeing’s Executive Vice president of Commercial planes quoted it compactly, “It has just noticed to be more problematic than we expected accomplishing the structural work on the airplane out of order in our Everett (Wash.) Factory.

The delay in project and its reasons

Boeing confirmed a total of 14 months delay in the project of development of the 787-Dreamliner, the most anticipated airplane of Boeing. This announcement of delay presents nonetheless a serious setback to the Boeing Company and according to a wall street journal; it was presented by some analysts that this delay caused about $4 billion in penalty payments for the missed deadlines.

According to the delayed schedule of Boeing, the test flight was then expected to be postponed to late 2008, and the deliveries to 3rd Quarter of 2009.

Reasons for the delay

According to the Seattle Times, 2008 there was a total delay of 27 months. The first delay that was initially announced in October 2007 was due to an unexpected shortage of fasteners of 787-“the nuts and bolts” of the airplane.

In January 2008 another delay was announced by the Boeing Company for 787, which was due to the start-up issues in the factory and the global supply chain issues. In April, 2008 the third delay for the Boeing 787 was announced by the officials. This delayed period according to the President of Boeing James McNarney was said to be in fact the result of the innovation that was going to be presented by this Dreamliner.

Delayed due to innovative features: The delay was basically due to the trials and errors that were being implemented to bring out the novel and innovative features;

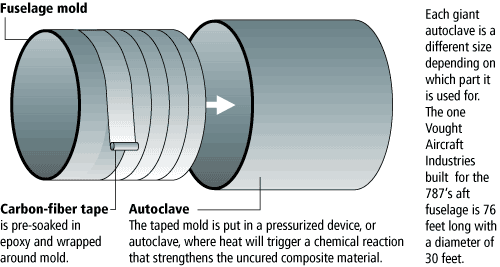

- The introduction of carbon filter technology had become a denting challenge for the engineers. They have to use this technology to prevent the parts becoming heavier as if the parts become heavy then the speed efficiency was affected, thus the major challenge in this regard was to balance these motives.

- Similarly the central wing box needed to be perfectly balanced so, for this engineers have to design a patch box, and then redesign the wing box which was of course a time taking activity.

- The initial outsourcing experience for the fuselages also proven to be a disastrous experience thus contributing to delay also.

The conclusion is that perfection was the mission to attain and the time limit communicated was too far and too difficult to achieve considering the demands of the perfections to be attained and the motives of the airplane, however furthermore the unfortunate strikes of the workers in the factory and other outsourcing hindrances served an additional delay thus damaging the image of the airplane and Company as well.

Confident design

According to Bair the ultimate goal was to develop up a composite structure and form of all the schemes and enhancements to develop a design with the same required economics as the 767, but it would surely run at the velocity of 20% enhancements in the speed.

Sonic Cruiser Concept

Due to its extreme improvement in speed efficiency it was called as “Sonic Cruiser Concept”. To improve this Sonic Cruiser Concept this plane moved with a 12-member inspection Team.

The commercial value of Dreamliner

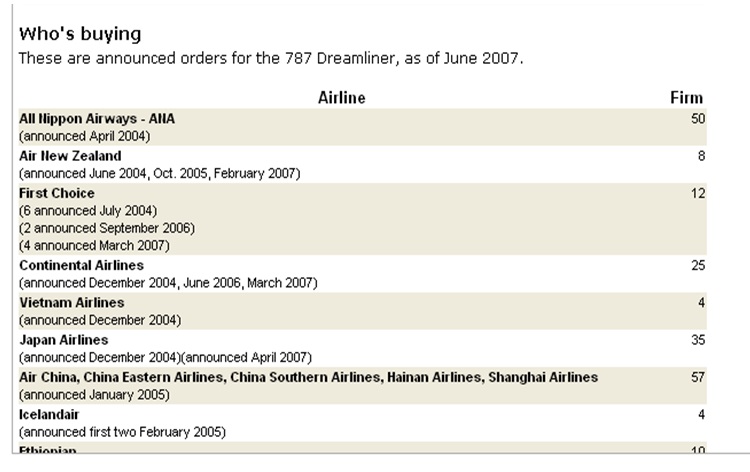

Boeing Dreamliner 787 has all the characteristics of redirecting and impressing the product policies of other manufacturing sectors. On the other hand, the aircraft is already attained. The case has been so commercialized that if now anybody wants to order for 787 then the expected delivery would be in 2015. This situation clearly interprets the commercial value of the 787 Aircraft. The following chart shows data of the customers who were holding orders for 787 by 2007.

Structural comforts for the passengers

Boeing has aimed to improve the Flying experience including the interior architecture. A unique interior has been demonstrated to the customers by selecting characteristics of seats, galleys and lighting. The cabin ceiling has been designed in such an artistic way to remove the effect of the presence of the ceiling instead of giving an impact of a broad sky. The features contributing to the exclusive comfort of the passengers are:

- Air Quality

- High Cabin pressure

- Windows

- Lightning

- Air Pressure

Increased air purification has been provided in the 787 cabin to let the passengers feel more relaxed and much more comfortable while traveling.

- High Cabin Pressure

The hardest composite body of 787 present’s huge cabin pressure around about 6,000-foot acme. This will lessen the effect of tiredness in passengers after flight.

- Lightening:

New LED lights have been utilized. The effect of lightening in the cabin changes with taking off and catering services and this entertains the passengers with comfort and relaxation.

- Windows:

The windows of 787 are renowned as the largest windows ever launched in the market. This gives the passengers a broad horizon view. The windows are made up of electrochromic.

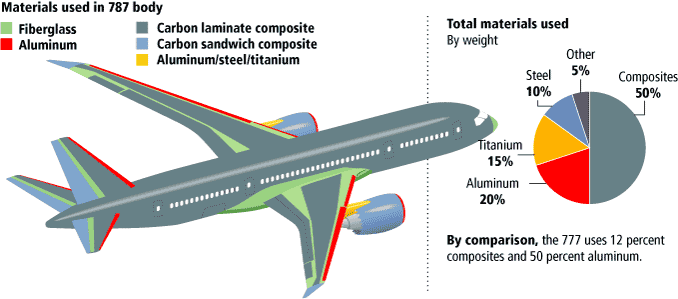

The technology presented

The preliminary objective on the technology discipline for Boeing was to invent a collection of materials to lighten the airframe. Extensive research has been implemented on Boeing 787, involving fuselage, no bleed-air engines and wings. The structure has been designed by keeping 50% composites by weight (80% by volume), 20% Aluminum, 15% Titanium, 10% steel, and 5% other.

Economical Aspects of design

Fuel Efficient

As stated by Boeing, the 787 Dreamliner will be 20 percent more fuel efficient as compared to the midsize 767 or Airbus A330 by using new engines, aerodynamic improvements, lighter-weight materials and other advanced engineering Technologies.

Composite Body

Partnering in the construction of Plane

Boeing has raised the depth of partner section in the 787 Program. This plane is developed in sections starting from all over the globe. Bair, bearing the responsibility of the head of the task says that Boeing’s 787 partners link to not less than 17 organizations from various countries and supply parts, sub-assemblies or linked components that surely reach by plane at Boeing’s Everett advantages for final assembly.

Bairs declares that “Boeing’s rationale for raising its outsourcing policy is an identity that the best procedure skills rapidly outside Boeing factories. Tokyo relied tray companies are designed for carbon fibers.

Future Perspectives for Boeing Company

Latest Technology with respect to the competition

Competition is growing and Boeing need to devise alternate was for comforting its customers to the best and also to keep the customers happy by providing the latest technology.

Secure and safe Journey

The company is growing and the faith of the passengers needs to be maintained by providing them with new solutions for their safe and secure journey.

Customer satisfaction

The ultimate aim of Boeing is to provide the customers a service that results into extreme satisfaction of its customers. The more the passengers are happy and travel with comfort the more the business will grow.

Economical Satisfaction

The company should also strive for the economical satisfaction of the passengers as cost-saving is a need of time.

Reference List

FAC,. (2004) Farnborough Aerospace Consortium. Japan: Scoping Mission Report.

JADC, (2005) Outline of Japanese Aircraft Development: Corporation. www.jadc.or.jp

Pritchard, D. and MacPherson, A.(2005) Boeing’s Diffusion of Commercial Aircraft design and manufacturing technology to Japan: surrendering the US Aircraft industry for foreign financial support. Canada-United states the Trade center State University of New York.