Introduction

This discussion revolves around the identification and description of a number of areas where Zoe’s Kitchen can make improvements, especially in areas of its operations, to develop a stronger market position. The paper also highlights the interrelationship between the areas of improvement that are suggested. While the discussion under different management principles and marketing principles appears under separate subtitles, there are still similarities in the passages in the paper. In general, Zoe’s Kitchen has an ongoing lean operations strategy that is working. However, Zoe Kitchen has to work on improving its delivery times in anticipation of the demand that will be brought by the “City of Culture” festivities in Manchester and the competition brought by start-up companies like ur-Lunch. Consequently, Zoe’s Kitchen will have met the most critical customer requirement in the catering business.

The Issues affecting Zoe’s Kitchen

Market Requirements

In Zoe’s Kitchen, quality covers the delivery of the most appropriate serving, according to client orders. Food has to remain fresh and served hygienically while it is in an edible state, such as being warm and with an appetizing smell (Goodman 2009).

Regarding speed and time, Zoe’s Kitchen measures performance based on the time between request and delivery, which it should work on improving at least to match the competitors (Slack et al. 2012).

Dependability entails doing things on time as promised when dealing with customers and suppliers. A business that relies on reputation as a key component in its commercial value, such as Zoe’s Kitchen, has to offer dependability at all costs. It succeeds by being true to its word, which implies that the business has to run a tight organization that cannot succumb to the limits of process deviation (Hamilton & Chernev 2013). Zoe’s Kitchen can make bold statements to its customers and be assured that it is never going to let them down because it embraces a predictable supply chain, which is a critical element in its value addition.

Zoe’s Kitchen faces demand for tailor-made foods and servings, which place a demand on the business balancing techniques. In the end, Zoe’s Kitchen has to match customer requirements with a high level of efficiency at all times. The business might have to make compromises on some of its product and service offerings so that it is able to remain flexible on the remaining customer service promises and deliver them (Ferrell & Hartline 2011).

The verdict is that Zoe’s Kitchen must keep staff numbers low, maintain a high inventory of purchased stock, and invest in technology at a medium scale to meet threshold performance objectives (Slack et al. 2012).

Customer Services

Zoe’s Kitchen has to identify the zone of tolerance that exists between the desired service and the adequate service and then work within this zone to meet its customer requirements. For example, it may not have to respond to all customers who want unique meals that are not on its menu, but it may find out that it cannot compromise its image by avoiding or disappointing customers who need delivery on short notice. It would be better for the business to charge an extra service fee for super-fast deliveries and still be able to make the timely delivery (Dawar 2013). In this case, the customer requires a fast delivery and will be frustrated when the delivery is late. Thus, lateness is beyond the zone of tolerance for Zoe’s Kitchen customer service. The mission statement and the way it aligns to meeting customer requirements would indicate Zoe’s Kitchen’s performance (Dawar 2013).

The employees will support the business’ mission to meet its organizational goals. With a mission, it is easy to fit individual decisions and actions into the broader picture. Understanding the industry allows Zoe’s Kitchen to compare its performance with that of its rivals (Dawson 2003). It can then strategize according to the views of the customers as they compare it with other businesses. For example, Zoe’s Kitchen risks being associated with older systems because some of its competitors like ur-Lunch are younger in the industry. Nevertheless, it can also use its reputation and its associated loyalty to win more customers by remaining true to its mission and service promises.

Capacity Management

With a job schedule, Zoe’s Kitchen is able to determine the amount of time and other resources needed for fulfilling its purpose (Brown et al. 2002). The company operates with a delivery schedule and a production schedule.

Focus and Scope of Business

Currently, Zoe’s Kitchen targets everyone within its market area in need of food deliveries. However, with heightened competition, the business will have to either expand its capacity to serve the entire market and deal will all kinds of rivals, or it can narrow down its focus to a niche market segment that it can access adequately. Zoe’s Kitchen can do better by using segments to differentiate targets. It can appoint business units for each identified market segment and then have different delivery standards and market objectives for the segments. Not only will the segmentation strategy allow the company to appeal to multiple consumer niches, but it will also allow it to offer different menu items to customers and still maintain a predictable production schedule.

Facility Location

The current target market for Zoe’s Kitchen is the entire Manchester area. The business has its facility in the area; therefore, it is able to meet its production commitments. Most of the deliveries are within the proximity of the production facility. Currently, the business can meet production schedules by stretching just a little. With the delivery time being a critical competitive determinant, the business will have to consider having multiple facilities within Manchester to move closer to delivery targets and shorten the delivery times (Chenet, Tynan & Money 2000). Without moving location, the addition of staff will only improve the business delivery schedules marginally. Different servings require the combination of foods to happen within the facility before shipment occurs. Therefore, the only way to hasten the process is by moving the food assembly and packaging processes towards the customers.

As already described in the focus management and capacity management, mobile packaging centers will provide a long-term solution that can be implemented in the short term as well. The business can start with simple ‘carry and package’ vans or trucks that allow workers to move around Manchester with raw ingredients and packaging material and then make tailored menu servings for customers on-site. This will work well with the upcoming “City of Culture” events held in the city of Manchester in the next year.

Process Layouts

The food preparation and delivery processes in Zoe’s Kitchen follow an optimal design for the business. The business relies on a two-stage process of scheduling. It creates schedules on Monday and handles ad-hoc schedules for ‘delivery only’ orders daily. Workers have fixed duties assigned to them; they sometimes perform variable duties in their assigned work zones. With clearly defined roles, it is easy to fit part-time staff in the business at peak demand times. Adequate facilities can help the business to store raw produce, but it cannot do the same for cooked food because it will compromise food quality (Balmer & Gray 2003). However, there is enough room to store ingredients and packaging material, which are easy to acquire in bulk. Going for bulk storage will only help when the business environment is predictable for the long term. In the catering industry case, packaging materials can change in the short term as a company changes its packaging to meet changing customer demand for new food menu items.

Materials Management

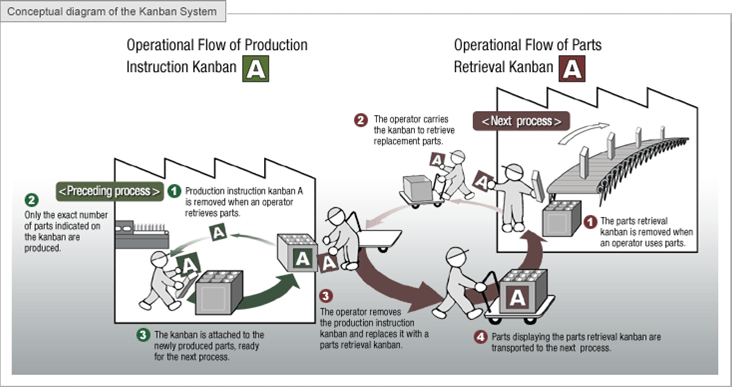

Just-In-Time (JIT) is a production philosophy that ensures the delivery of products or services only happens when they are needed. It implies that Zoe’s Kitchen will get a supply of products and services just when it needs them. On the other hand, it will only deliver foods to customers based on their needs. On one side, there is the operation of the business, which deals with production resources. On the other side of the business arrangement, there are operations dealing with customers (Slack, Brandon-Jones & Johnston 2012). The purpose of the Just-In-Time philosophy is to have a stockless production, lean synchronisation, and zero inventory.

Supplier Selection/Relationships

The business is currently handling its purchasing obligations well by ensuring that it has supplies when it needs them; it has not encountered any shortages. This report assumes that Zoe’s Kitchen has made long-term arrangements with its core suppliers to provide the ingredients at favourable prices. As the case study explains, Zoe’s Kitchen only has permanent employees to cater for its scheduled operations. The business hires part time employees when demand increases. Therefore, it handles the labour resource adequately.

Analysis

Marketing

Marketers and management staffs have access to five operational objectives that add value to customers and ensure that their business remains competitive at the same time. The objectives, when met, lead to better market performance of the business, as shown by positive reception and improved revenues. The five objectives are quality, speed/time, dependability, flexibility, and costs. Flexibility covers product mix, volume, and delivery. Cost covers staff, purchases, and technology.

Quality calls for doing things correctly and getting it right on the first time. It implies that there should be no errors and every action or response by a business should fit a purpose and meet a specification. In a service provider company like Zoe’s Kitchen, quality also doubles as a production company because of the food business; the last word on the company’s reputation remains quality. Poor service causes a lingering bitterness that overcomes any sweetness that would have been earned in prior relationships with the customer.

Speed is all about doing things fast and reducing the lead-time. Speed questions and objectives cover the goal of minimising lag. In the restaurant business, quoting a super-fast turnaround time between ordering and order delivery remains a salient differentiator for the top performers from the loss makers. However, delivering on time in full requires investments and strategic considerations on the internal value chain. Any lag within the system has to disappear, thus a business must opt for a lean production process to reduce waste in timed deliveries.

Flexibility covers the variability of customer demand and the ability of the business to comply with the changes, irrespective of their critical nature and time allowance. At the same time, it looks at the abilities of the business to introduce new products and services to customers to meet their ever-changing demands (Goodman 2009).

Cost as a marketing requirement will cover all the aspirations of the business to do things cheaply. The ability of Zoe’s Kitchen to produce meals and deliver or serve them at a price that is right for the market will allow it to earn considerable margins on top of its costs. The only way to achieve the cost objective is to have a stock replenishment system that allows volume production present a balance to the economic batch size or typical meal delivery and the cost point per unit as prescribed by the meals served by Zoe’s Kitchen to customers (Ferrell & Hartline 2011). Where the company cannot use the strategy, it has an option to increase its profit margin by customization and personalization, allowing Zoe’s Kitchen to go with smaller batch production and still avoid waste overheads.

Customer service

Customers have beliefs about service delivery that they hope a business will fulfil. They judge the performance of the business based on the matching of expectations and delivery outcomes. Customer requirements vary by industry, business, and circumstances. Restaurants and food delivery businesses like Zoe’s Kitchen face a continuum of customer requirements. There are ideal expectations or desires expressed by customers when the reputation of the business is very high. However, customers can still expect tolerable service and products and continue to order food from the restaurant because of its low-price point.

Working according to a standard allows the business to remain dependable and to fulfil its customer requirements. The set standards have to be within the tolerable zone of customer expectation. For example, Zoe’s Kitchen can have a straightforward standard implying that it will always deliver on time and then work out mechanisms to ensure it does so when customers demand.

Capacity management

Zoe’s Kitchen has potential capacity, immediate capacity, and effective capacity measured in units of work. Time is the biggest constant of Zoe’s Kitchen, as customers require deliveries on time. Capacity is also a constant because businesses can only serve a given number of customers at any time. According to the case study, the business receives a constant amount of orders for deliveries and deliveries-plus services in most months of the year. During peak times, it manages the extra capacity demand by hiring part-time staff and relying on additional labour from Steve, the co-owner.

Supplier selection/relationships

A business can sustain its competitive advantages by improving its supply chain and network management. The objective is to reduce the inventory of the business in line with its objective (Slack et al. 2012). In this case, Zoe’s Kitchen will be seeking to reduce inventory and wait times, such that it complies with its Just-In-Time operations’ objectives. The purchasing function is crucial for any business.

Key issues

Zoe’s Kitchen has predictable working hours and ordering timelines; it maintains a reasonable queuing time. The important thing is to improve the wait times even marginally and maintain the new promise, rather than improve considerably only to fail in the future (Slack et al. 2012).

Zoe’s Kitchen should consider increasing its menu items by creating additional combinations of the same ingredients; it must also opt for an addition option, in addition to delivery and service or delivery only. It should also look into going to a niche market to adjust customer numbers and be able to fulfil new demands.

In Zoe’s Kitchen context, the JIT process will imply that the business has to make sure there are zero defects in the packaged foods and zero complaints about customer service when delivering the food or when dealing with customer inquiries (Doorey 2011). Another aspect that the business has to look at is zero set up and zero handling times. The Just-In-Time application to Zoe’s Kitchen must focus on the time taken to do any activity related to food production and service delivery. Another business risk that the Kitchen should not take is the ordering of food in bulk without having sufficient storage capacity (Slack, Chambers & Johnston 2011).

Zoe’s Kitchen requires a constant supply of fresh products to make the different foods that it serves. It also needs equipment for its kitchen production facility and the workers. Zoe’s Kitchen needs packaging material and delivery resources, such as vehicles, telecommunications equipment, and related technologies.

Zoe’s Kitchen capacity limitation is in deliveries; thus, the business will need to embrace technology and set up a robust and highly efficient delivery schedule. Production schedules adhere to delivery dates, job schedules, capacities of production, efficiency of the production units, and anticipated shortfalls. In Zoe’s Kitchen case, the company has to consider the absenteeism caused by a number of reasons.

Solution for key issues

It might include the detachment of some packaging processes from the main facility to mobile locations, such as a food delivery van, so that employees can quickly make a menu serving on site and make a delivery while they are on their way to other delivery areas. While working with production schedules, the company will also have to delegate decision making to workers so that they can make timely decisions about a particular format of making deliveries to clients, as long as it meets the set out customer requirement standards. Short-term changes would include hiring extra part time staffs, while the business should get the customized delivery vans that combine packaging and transport processes, and they have adequate communication equipment to take orders on the go in the long-term (Abratt & Kleyn 2012).

Zoe’s Kitchen can then make appropriate advertisements to woo customers in its defined segments. Combined with mobile packaging options, the segmentation will allow Zoe’s Kitchen to assign different vans or trucks to different regions for geographic targeting and then equip and stock the vans with specific foods and packaging material to cater to their target niche.

Using Porter’s generic strategy, Zoe’s Kitchen would be best served by a differentiation strategy. This would be marked by product uniqueness and a target scope that is broad, covering the entire geographical area of its location. With the focus strategy, Zoe’s Kitchen would make its delivery unique, dependable, and tailored to customer needs. It can then afford to charge premium prices on some of its products and still make adequate sales.

Rather than focus on increasing storage, Zoe’s Kitchen can concentrate on having multiple supplier relationships and supply contracts that allow it to maintain agile operations and still keep the costs low. On deliveries, it can lease vehicles instead of buying and dealing with lease-on-demand companies when demand increases. In the catering industry, being lean in operations and maintaining agility in delivery times is a competitive advantage worth acquiring.

Conclusion

The immediate business demands of Zoe’s Kitchen revolve around the need to improve delivery times. Its biggest rival ur-Lunch has an advantage of being set up near clients. Its close proximity allows it to service clients’ needs at a shorter time compared to what Zoe’s Kitchen offers. In this regard, recommendations for the business are that it should reduce the overall time it takes to service the orders from clients. To do this, the business will have to improve the overall time it takes to come up with new food menu items so that servicing the foods will be easier when there is new a demand. With proper relationships with suppliers, the business can flourish by having most of its food menu items delivered to its facilities in pre-packaged forms; the business can save on the time taken to process orders on its facilities. Moreover, maintaining effective supplier relations will ensure that the quality of food delivered to the business remains high throughout. The biggest determinants of success in Zoe’s Kitchen are its food quality and delivery times, with customer serving playing a complementary role. A suggestion for improvement in the long-term is to purchase customized delivery vans or trucks that will allow workers to respond to new orders while they are on the move.

References List

Abratt, R & Kleyn, N 2012, ‘Corporate identity, corporate branding and corporate reputations – reconciliation and integration’, European Journal of Marketing, vol. 46, no. 7/8, pp. 1048-1063.

Balmer, JM & Gray, ER 2003, ‘Corporate brands: What are they? What of them?’, European Journal of Marketing, vol. 37, no. 7/8, pp. 972-997.

Brown, T, Mowen, J, Donavan, DT & Licata, JW 2002, ‘The customer orientation of service workers: Personality trait effects on self and supervisor performance ratings’, Journal of Marketing Research, vol. 39, no. 1, pp. 110-119.

Chenet, P, Tynan, C & Money, A 2000, ‘The service performance gap: Testing the redeveloped causal mode’, European Journal of Marketing, vol. 34, no. 3/4, pp. 472-497.

Dawar, N 2013, ‘When marketing is strategy’, Harvard Business Review, vol. 91, no. 12, pp. 100-108

Dawson, M 2003, The consumer trap: Big business marketing in American life, University of Illinois Press, Illinois.

Doorey, DJ 2011, ‘The transparent supply chain: From resistance to implementation at Nike and Levi-Strauss’, Journal of Business Ethics, vol. 103, pp. 587-603.

Ferrell, OC & Hartline, M 2011, Marketing strategy, 6th edn, South-Western, Cengage Learning, Mason, OH.

Goodman, JA 2009, Strategic customer service, AMACOM, New York, NY.

Hamilton, R & Chernev, A 2013, ‘Low prices are just the beginnning: Price image in retail management’, Journal of Marketing, vol. 77, pp. 1-20.

Slack, N, Brandon-Jones, A & Johnston, R 2012, Operations management , 7th edn, Pearson, New York, NY.

Slack, N, Brandon-Jones, A, Johnston, R & Betts, A 2012, Operations and process management, 3rd edn, Financial Times Press.

Slack, N, Chambers, S & Johnston, R 2011, Operations Management, 6th edn, FT Prentice Hall.

Appendices

Appendix 1: Table Showing Analysis of Customer Perceptions of Zoe’s Kitchen

Appendix 2: Just-In-Time Process Illustration for Inventory Management

Appendix 3: a Self-catering Trailer

An illustration of a self-catering trailer that would attach to a van or truck for mobile packaging and delivery of food

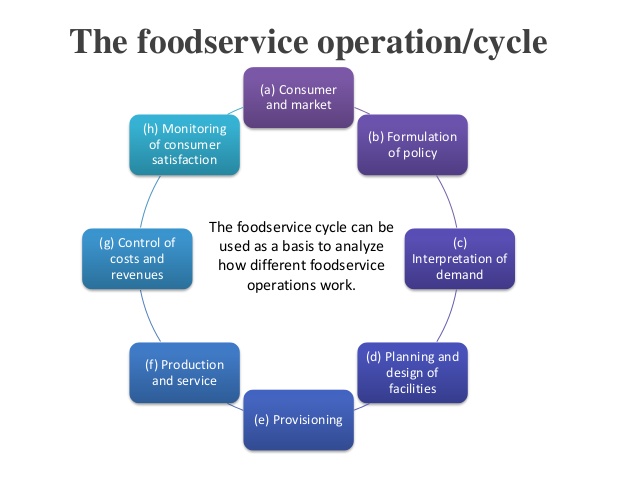

Appendix 4: A Foodservice Operation Flow Chart

The foodservice operation flow chart is applicable to Zoe’s Kitchen catering services.