A supply chain map usually offers the basis for modifying or redesigning an already existing supply chain. It allows an individual to visualize the supply chain and identify areas that require much analysis to be rectified. It also reveals inefficiencies that are only visible when one segment of the supply chain is examined. This paper aimed to analyze how supply chain mapping was critical in completing the cliff lighting project used for Qiddiya Iconic Cliff.

The stakeholders of the project have been highlighted concerning their impact. The contracted company sourced materials and labor from within and outside the kingdom. The external sourcing of materials puts the company at a greater risk of bearing the unforeseen events that usually harm the supply chain, thus negatively affecting procurement functions. The paper has recommended various ways by which these unexpected events can be mitigated, thus resulting in an efficient supply chain and effective procurement process.

Introduction to Qiddiya Project

The Qiddiya project is a $500 billion entertainment megaproject unveiled in 2019, and it is scheduled for opening in 2022. Located just 40 km away from downtown Saudi Capital Riyadh, the project aims to make Qiddiya the capital of entertainment, sports, and the arts in Saudi Arabia. The project is based around five cornerstones parks and attractions, arts and culture, sports and wellness, motion and mobility, and nature and environment. The real estate and community services unit will create a thriving community with 5000 residences that will support the cornerstones (Al-Qiddiya, 2018).

The project will cover approximately 34 km2 of the 334 km2 area allocated for the development. The remaining space will be left for safari and future expansions. The site is also characterized by unique mountainous terrains that feature multiple highlands and 200m high cliffs. Due to the project’s grandiosity, several contractors have been enlisted to make the Qiddiya dream a reality.

About the Contracts Department

Through the Qiddiya Investment Company (QIC), several local and international companies have been awarded contracts in various sections of the Qiddiya project. The aim of awarding the different contracts has been pegged on delivering the contract at the stipulated time without compromising quality and working within the assigned budget (Al-Qiddiya, 2018). The Losberger De Boer, sponsored by the UAE-based event management company, Duvent, is the project’s main contractor. Shibh al-Jazira Construction Company has been contracted to develop roads and bridges that will connect the planned resort to the main highway. DuBox Company has been awarded the contract of building a 2,000-sq-m building on the Qiddiya site.

The placing of security fencing around the entire premises of Qiddiya will be done by the Saudi Pan Kingdom Company (SPAC). As such, almost every sector of the project has contractors on site ready to deliver. Qiddiya will have a separate power grid, which implies that the project is looking to award a contract through the public-private partnership (Al-Qiddiya, 2018). The contract’s scope will be power generation, waste management, water desalination capacity, and wastewater treatment facilities.

Scope of this Assignment

The Qiddiya project is ambitious; thus, it is impossible to touch on almost every aspect of the project as far as the contracting works are concerned. Qiddiya has several high cliffs that give the site a scenic view, and QIC is looking to capitalize on that to offer great entertainment to the many visitors who will throng the area. Thus, the study’s research is based on the cliff lighting project used for Qiddiya Cliff and its supply chain. The study aims to assess, analyze, and contrast the supply chains’ strengths and weaknesses and their impact on the company and each business unit.

Mapping of Supply Chain

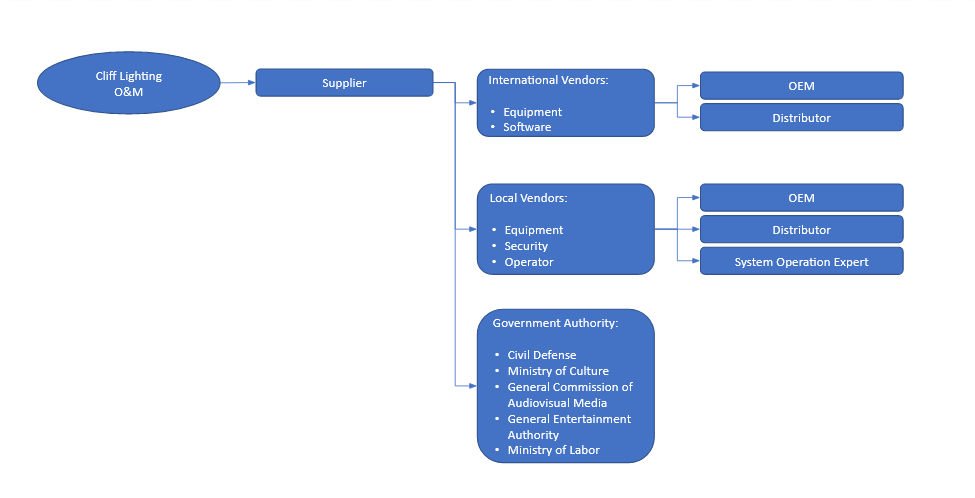

The transparency and visibility enabled through the supply chain mapping create trustworthiness among the project’s stakeholders. The contractor can easily monitor the source of the materials needed for the project and even make adjustments to the required customized components. Ideally, the contractor’s supply chain mapping alleviates concerns surrounding the quality of goods used for the project. Therefore, if the project is completed earlier than its stipulated date, it does not fail to meet the Saudi people’s expectations (Garrido et al., 2011). The transparency and visibility also ensure that the contractor sourced the project materials from suppliers that complied with regulations relating to ethical issues such as modern slavery and responsible sourcing. Figure 1 “Supply Chain Mapping of the Cliff Lighting Project” illustrates the principle of transparency by elucidating both international and local supply sources as well as pointing out Saudi government authorities that oversee the project.

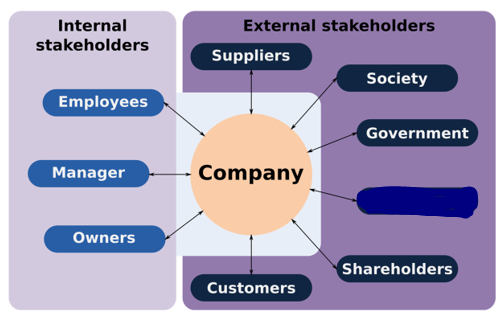

Figure 3 demonstrates the internal and external stakeholders of the Qiddiya projects. As seen in Figure 3, stakeholders are a broader group than suppliers. There are several approaches toward understanding stakeholders in supply chain management with the most pertinent to the current project being UPIG. The abbreviation stands for Users, Providers, Influencers, and Governance (Miles 2017). In the case of the cliff lighting project, Saudi society as a whole and tourists and visitors, in particular, are the Users.

Suppliers specified in Figure 2 fall under the Providers category. Shareholders and the government are interested in having the project carried out timely and up to their standards, which puts them under Governance. Lastly, managers and owners to a greater extent and to a lesser extent employees are the Influencers of the project as they have the leverage to change the direction of the project.

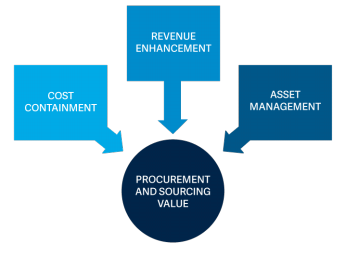

Supply chain mapping minimizes risk and ensures that a contractor gets value for his money. Increased visibility and risk management go hand-in-hand for an operation to be as effective as possible. Through the mapping, the contractor dramatically reduces the risk of suffering damage to their finances, reputation, and even legal standing. Figure 3 shows exactly how the Qiddiya project will drive value through procurement and supply. As seen in the figure, value creation hinges upon three aspects: cost containment, revenue enhancement, and asset management.

Supply Chain Mapping of the Cliff Lighting Project

Driving Value Through Procurement and Supply

Stakeholders Mapping

Analyzing and Contrasting the Supply Chain

The timely delivery of quality construction materials and equipment is vital in the construction industry. Supply chains play an influential role in ensuring that quality material reaches the site on-time. It is usually made possible through supply chain mapping. An ambitious project like Cliff Lighting requires a highly complex supply chain involving multiple suppliers and vendors that must be coordinated to yield the desired results. The complexity has made it challenging to identify a disruption or a bottleneck whenever it occurs. Thus, without identifying the source and the cause of the problem, achieving the targeted sales and growth has sometimes proved difficult.

Supply chain analysis is the process that involves evaluating every stage of a supply chain, starting from the time raw materials are acquired by a business or receives supplies from its suppliers to the delivery of final products to the customers. The analysis critically determines the areas that can be improved or shortened to ensure quick and efficient delivery of products to the customer. The supply chain mapping is embedded in the philosophy that the more flexible a business can be, the faster a company can achieve the desired growth rate. From a construction perspective, the flexibility of a company ensures the timely completion of a contract.

At present, there exists a plethora of supply chain analysis techniques – both quantitative and qualitative. The application of the PESTEL analysis will promote the awareness of political, social, economic, environmental, technological, and legal issues. Below is the analysis of the present supply chain from the PESTEL standpoint:

- Political factors. The Qiddiya project is overseen by multiple government bodies, such as the Ministry of Labor, the Ministry of Culture, and the Ministry of the Civil Defense. Among these, the most pertinent institution is the Ministry of Culture that was only established in 2018 but already tasked with diversifying the country’s traditionally oil-based economy (The Ministry of Culture, 2019). The cliff lighting project is consistent with the cultural vision developed by the Ministry of Culture that strives for enhancing tourist inflow and enhancing Saudi residents’ quality of life by creating culturally significant sites and venues. As for external politics, Saudi Arabia has cultural ties and amicable relationships with the Gulf States as well as cooperates with global superpowers, such as China and the United States.

- Economic factors. Between 2013 and 2017, the Kingdom had been increasing its expenses on the tourism sector. If in 2013, tourism expenditures made up 2.24% of the country’s exports, by 2017, the number had reached 6.19% (Macrotrends, 2019).

- Social factors. Saudi society is growing to appreciate art and culture, which explains a surge in the popularity of domestic tourism. In 2020, domestic travel figures exceeded expectations despite the global tourism industry slump (Tashkandi, 2020). Another social trend is the liberalization of art that until recently, was confined to a small group of Saudi artists.

- Technological factors. Saudi Arabia is committed to becoming a leading data-driven economy. It is estimated that by 2030, the adoption of artificial intelligence will add 135 billion to the national economy, making up one-eighth of GDP (SDAIA, 2020). Currently, the Kingdom has founded the Saudi Data and Artificial Intelligence Authority (SDAIA) and tasked the institution with storing and curating datasets to aid the economy (SDAIA, 2020). Leveraging data analytics may be key to building a sustainable supply chain.

- Environmental factors. Currently, the Kingdom of Saudi Arabia faces many environmental problems mainly associated with desertification and solution. Because environmental protection is part of the future vision, the Qiddiya suppliers will have to make environmental considerations when carrying out the project.

- Legal factors. Amending and enforcing contract law in Saudi Arabia is a responsibility of the conservative Hanbali school of Sharia law. Foreign contract laws are generally enforceable unless their nature is explicitly prohibited in Quran.

All points taken into consideration, it is safe to assume that external factors work in favor of the Qiddiya project. The supply chain is characterized by the government’s involvement, which is standard for the Kingdom of Saudi Arabia. Yet, in this case, the involvement means ongoing support and avid interest in the success of the project. The Kingdom has sufficient funds to carry out the Qiddiya projects as it is aligned with its tourism development plan.

The presence of international and local vendors does not add unnecessary complexity to the supply chain but rather benefits it. Williams (2019) writes that in recent years, the country has undertaken a multitude of megaprojects, which puts immense pressure on local supply chains. In this case, outsourcing to international vendors may serve as a relief as well as an opportunity to exchange experience. It is highly unlikely that the Qiddiya team will experience any issues with enforcing foreign contracts because they do not include immoral, risky, or gambling activities.

Strengths and Weaknesses of the Supply Chain

The construction industry is one sector characterized by a great deal of uncertainty. For instance, the absence of material can easily lead to the suspension of a project. Shortages might severely impact the contractor plus the workers who heavily depend on the project for their daily livelihood. The project’s suspension may also mean delay, which would be an unfavorable turn of events for all stakeholders. Therefore, it is essential to assess all strengths and weaknesses of the supply chain. To do so, a tool known as SWOT will be applied:

- Strengths. An inarguable strength of the present supply chain is a mix of international and local vendors that ensure the viability of the project and the abundance of the necessary resources. Some of the chain’s influential stakeholders, employees, and managers also contribute to procurement. On the whole, the City of Qiddiya requires 17,000 to be run with a part of them allocated to maintain the cliff lighting project. Currently, the government introduced a number of scholarships and training courses (some of them in collaboration with the University of Central Florida) to educate Saudi cadres on hospitality and tourism. Therefore, the supply chain benefits from ties with suppliers nationwide and across the borders and an educated workforce.

- Weaknesses. In general, construction is one of the most dangerous industries worldwide. Saudi Arabia is not an exception as here, construction workers still fall victim to workplace hazards at alarming rates. Mosly (2015) writes that in Saudi Arabia, construction accidents make up 34% of all workplace accidents. An open-air outdoor venue with a natural landscape like Qiddiya may only increase the risk of accidents. The project’s employees may suffer from fatigue and heating on-site. Another weakness lies in Saudi Arabia’s poor nationwide level of English language proficiency. Yet, an excellent command of the English language is a must for coordinating international vendors.

- Opportunities. The Saudi government is committed to expanding the national cultural heritage and investing in the tourism sector. Therefore, the Qiddiya cliff lighting project will enjoy state funds and continuity of procurement. The pandemic hit the tourism sector hard but incentivized Saudis to travel domestically. Appreciation of local sights will translate into more revenue, adding value to the project and meeting the stakeholders’ expectations. Furthermore, art liberalization and strengthening ties with other countries may mean the inflow of new cadres, visions, and ideas. Qiddiya cliffs are versatile and can be involved in many events and collaborations, including foreign artists and investors.

- Threats. It usually takes just one part of the supply chain to break down and impede a company’s ability to deliver products and make money. Since much of the materials needed for the cliff lighting project had to be sourced outside the kingdom, the contractor would have been at a greater risk of inconveniences caused by natural disasters or artificial disasters such as political instability (Blackhurst et al., 2018). When these events happen, it implies that supply is not possible, and the impossibility implies that work will not be delivered within the stipulated time. Besides, conflict may arise between the stakeholders and this may hamper the timely delivery of supplies or completion of the project.

Impact of the Supply Chain Issues on Procurement Function

The role of supply chain and procurement in a company is usually to help with maximizing profits. By balancing supplier quality, cost reduction, supply assurance, and increasingly unlocking supplier innovation, a business assumes a better position to maximize its profits. Procurement provides suppliers with customers and helps the manufacturers drive innovation and bring products to the market faster and higher margins. Problems may occur when trying to mitigate and account for unforeseen delays somewhere along the supply chain. It is always difficult to predict and safeguard against unexpected delays in a supply chain, impacting procurement function (Pereira et al., 2014). Fluctuations in the availability of raw materials, adverse weather, staffing problems, political issues, hold-ups in customs, and legislation changes, among other hurdles, always delay the optimized procurement process.

Even though delay forms the core of the supply chain, thereby negatively impacting procurement function, it can still benefit procurement. It is usually more comfortable for a company to do an inventory through supply chain mapping and thus get to know what is needed earlier, thus placing a procurement order for the material or product. The early notice provides the supplier with ample time to design, manufacture, procure the item, and ship it to the customer and for payment processing (Pereira et al., 2014). Thus, in the end, the client and the supplier end up maximizing their profits due to cost-effectiveness. Through improved risk mitigation, the supply chain ensures the delivery of procured items, impacting the procurement functions. Before procurement takes place, it is always required that one assess the need for procuring the item, identifying a qualified supplier, and negotiating terms. The supply chain mapping usually ensures better collaboration of information flow that delivers quality products at a higher efficiency rate.

Conclusion

Today’s business world has changed a lot, and thus it requires one always to be vigilant when engaging in any business dealing. The supply chain has continued to play a critical role in enabling businesses to grow and help the world build breathtaking features such as the Qiddiya Iconic Cliff. Today, the Qiddiya Iconic Cliff is a reality thanks to supply chain mapping that ensured that the contractor’s items are delivered without delay. Even though the project achieved its goals, the challenges caused by unforeseen events should not be taken lightly. Supply chain mapping provides ways by which the said unfavorable events could be mitigated. Risk management ensures the continuous flow of goods and materials from the supplier to the client, consequently promoting procurement.

Recommendation

Supply chain management is a multi-faceted process that relies on and is influenced by a plethora of stakeholders. Any supply chain comprises multiple moving parts whose effective management requires proper mapping. The continued advancement in technology has not been well integrated into supply chain management, which may account for unforeseen setbacks. Technology may be the answer to the various challenges in supply chains. Hence, it is critical to invest in the right technology to enable productivity and attract profitability. However, technology is not the end-all-be-all of supply chain management as there are some supply chain mapping challenges that they may fail to address. These recommendations include:

- Maintaining constant communication with the suppliers. The supply chain map only shows the delivery patterns, but one should keep the supplier engaged in giving the update of the supply for on-time delivery.

- It is also vital for one to have buffer stocks on-hands at all times. To protect against unforeseen events, one must have reserves that could last until the new stocks arrive.

- Companies need to optimize their supply chain through data, information and using automated processes to make decisions. Investing in data and analytics enables companies to be flexible in creating solutions if the emergence of an unforeseen event.

References

Al-Qiddiya (2018) Al-Qiddiya Fact Sheet . Web.

Blackhurst, J., Rungtusanatham, M.J., Scheibe, K. and Ambulkar, S. (2018) Supply chain vulnerability assessment: a network based visualization and clustering analysis approach, Journal of Purchasing and Supply Management. 24(1), 21-30. Web.

Garrido, S. A., Machado, V. H., Barroso, A. P. & Cruz, M. V. (2011) Mapping and its importance to supply chains: a case study, Chinese Business Review. 10(7), 532-541.

Macrotrends. (2019) Saudi Arabia tourism statistics 2003-2020. Web.

Miles, S. (2017) Stakeholder theory classification: a theoretical and empirical evaluation of definitions, Journal of Business Ethics. 142(3), 437-459.

Mosly, I. (2015) Safety performance in the construction industry of Saudi Arabia, International Journal of Construction Engineering and Management. 4(6), 238-247.

Pereira, C.R., Christopher, M. and Da Silva, A.L., (2014) Achieving supply chain resilience: the role of procurement, Supply Chain Management: An International Journal. 19(⅚), 626–642.

SDAIA (2020) Data and AI to add more than USD 10 billion to Saudi Arabia’s economy. Web.

Tashkandi, H. (2020) Saudi domestic tourism bucks trend amid global travel slump. Web.

The Ministry of Culture (2019) Our Culture, our identity. Our cultural vision for the Kingdom of Saudi Arabia. Web.

Williams, A. (2019) HKA: Saudi Arabia supply chain may face ‘unprecedented pressure’. Web.

Bibliography

Ali, A., Mahfouz, A. & Arisha, A. (2017) Analysing supply chain resilience: integrating the constructs in a concept mapping framework via a systematic literature review, Supply Chain Management: An International Journal. 22(1), 1-49. Web.

Al-Qiddiya (2018) Al-Qiddiya Fact Sheet. Web.

Blackhurst, J., Rungtusanatham, M.J., Scheibe, K. and Ambulkar, S. (2018) Supply chain vulnerability assessment: a network based visualization and clustering analysis approach, Journal of Purchasing and Supply Management. 24(1), 21-30. Web.

Garrido, S. A., Machado, V. H., Barroso, A. P. & Cruz, M. V. (2011) Mapping and its importance to supply chains: a case study, Chinese Business Review. 10(7), 532-541.

Pereira, C.R., Christopher, M. and Da Silva, A.L., (2014) Achieving supply chain resilience: the role of procurement, Supply Chain Management: An International Journal. 19(⅚), 626–642.